At productronica 2021 we will present with our cooperation partner Emil Otto a newly developed solder with the following alloys Sn96.5Ag3Cu0.5 and AOX755, SnCu0.7Ni0.05Ge, better known as Sn100C. The solder wire is filled with a high-performance flux consisting of a newly developed fluxing agent.

The new, innovative and trend-setting flux system guarantees excellent soldering results from hand soldering to wave soldering and laser soldering. Processing is virtually splash-free, with minimal smoke development, with excellent residue behavior, leaving no dark discoloration or sticky residue. The soldering results are excellent.

This halogenide-free high-performance flux was specially developed as a flux filler for the production of lead-free soft solders. The flux is based on a high-purity synthetic resin in combination with a unique synthetic activation complex and therefore meets even the highest quality production requirements.

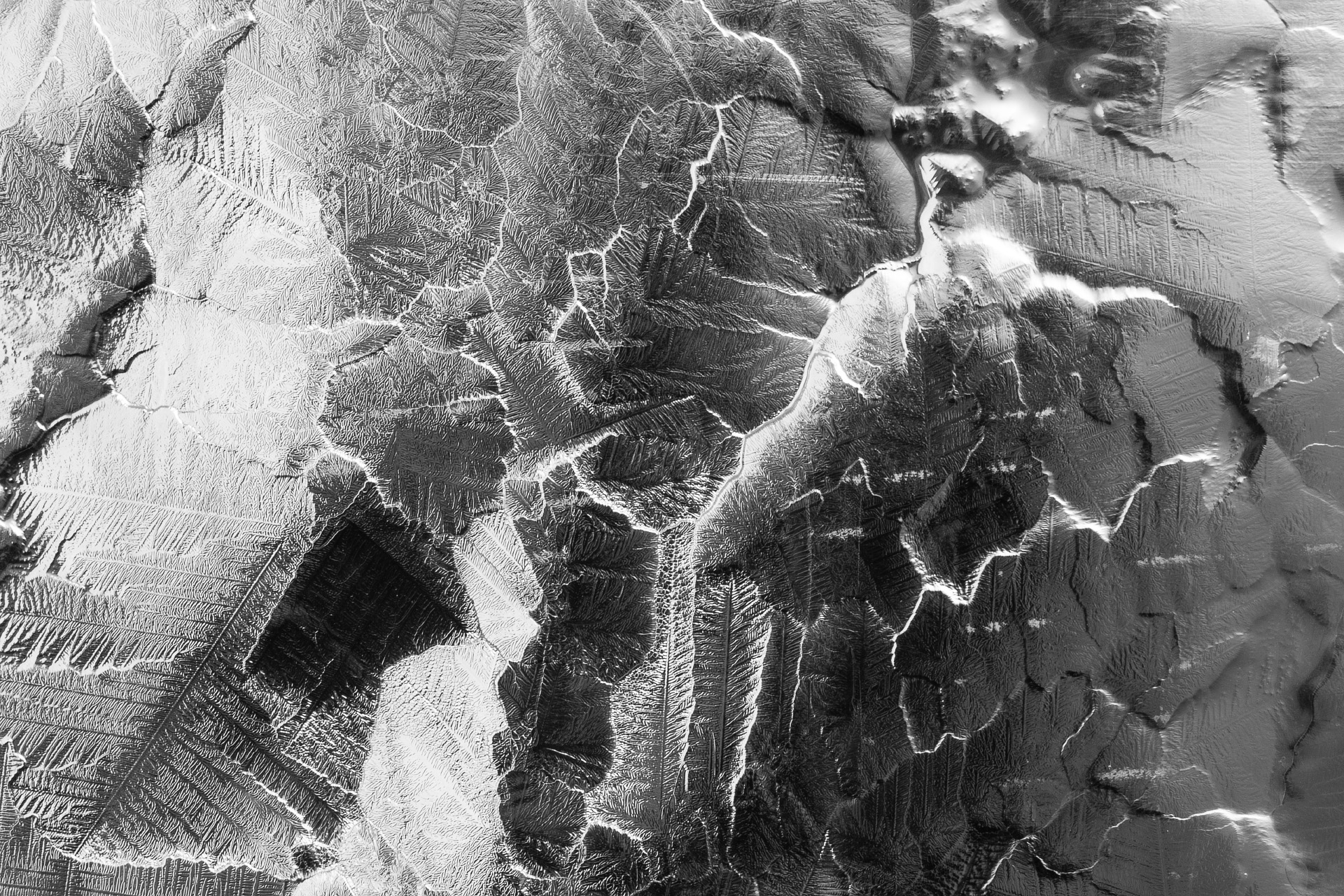

The activation effect of this filler is more than equal to that of previous halogenide-containing fillers. One of the development approaches was to reliably avoid hygroscopy of the filler itself and the crystal growth often associated with fluxes containing halides.